December 15, 2023

Snail-Like Robot Combats Microplastic Pollution in Water Environments

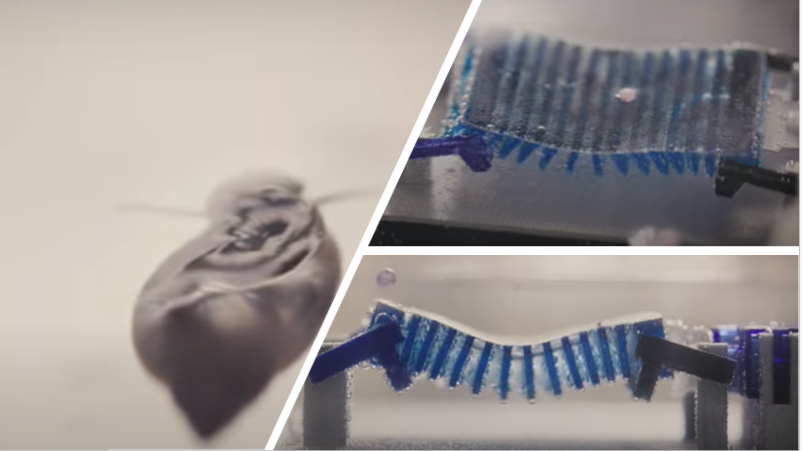

Scientists drew inspiration from the Hawaiian apple snail to create a cutting-edge snail-like robot that can collect microplastics from the surfaces of oceans, seas, and other bodies of water. The Hawaiian apple snail is commonly found in water environments, and it is known for its strange feeding behavior in which it employs undulating motion of its foot to generate water surface flow, allowing it capture floating food particles. Current plastic collection devices mainly use drag nets or conveyor belts to capture and remove plastic debris from water. Unfortunately, these methods are ineffective in retrieving microplastics. This is where the snail robot device can provide a solution. Built using 3D printing, its design consists of a flexible carpet-like sheet with a helical structure. Its unique design allows it to mimic the snail’s undulating motion, enabling it to travel on the water’s surface. A vital part of the research was the analysis of fluid motion to understand pumping behavior. The snail-inspired device’s open system demonstrated improved efficiency over closed systems that require high energy inputs. At a small scale the device operates on only 5 volts of electricity, while efficiently capturing water. While the prototype showed promise at a small scale, the device needs to be scaled up for practical deployment. Learn more about this topic here.

December 31, 2023

Kistler’s New Software Features Cross-System Data Analysis for Injection Molding

Kistler’s New Software Features Cross-System Data Analysis for Injection Molding

Kistler is promoting injection molding digitalization with its AkvisIO IME software, which allows synchronous cross- system analysis of data. AkvisIO IME (injection Molding Edition) includes analysis software for recording, storing, and analyzing high-frequency sensor data and machine signals during the injection molding process. The new software tool replaces the former data management software ComoDataCenter (CDC). New added functions included with AkvisIO IME are an analysis function and automatic data synchronization with connected systems. The new software’s key function is that it allows all data from machines and process monitoring systems, like ComoNeo and ComoScout units, to be visualized and analyzed synchronously across processes. The seamless integration of ComoNeo and ComoScout systems allows digital assets like tool configuration, reference curves, and monitoring objects to be transferred and managed on the AkvisIO platform and directly on the machine. In addition, all data will be saved on a cyclical basis, enabling the comparison and analysis of data across cycles. The creation of customized quality assurance reports is also enabled thanks to cross machine and cross-device monitoring of all processes. Kistler says that its AkvisIO is modular and scalable, a feature that will allow the continuous expansion of its many analysis features. Learn more about this topic here.