The main factor to a quality plastic injection molded part is a precise mold, one that produces reliable pieces time after time. Mold flow analysis is key in demonstrating the mold will perform as expected. We participate in plastic flow simulations as a stand alone service or as part of a larger design project that includes mold design. If you are looking for mold flow analysis companies, then BHC Associates should be at the top of your list!

What is Mold Flow Analysis?

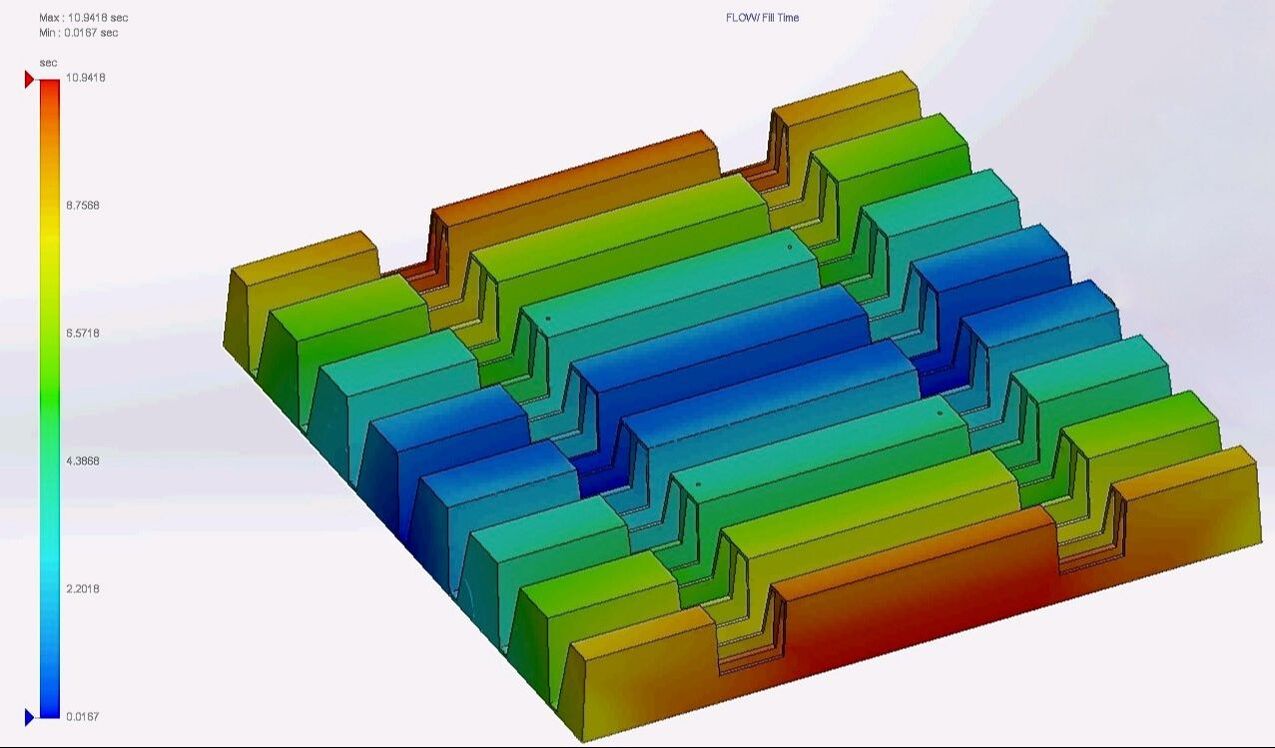

Mold flow analysis (MFA) is a software simulation showing how resin will flow through a mold. Once a mold design is complete MFA is used to determine the number of gates and their locations, show material choke points and hot spots, predict short fill and sink mark locations, and many other critical parameters needed to optimize a mold design for a repeatable, consistent molding process.

This analysis is vital to predicting what to anticipate during the molding process including:

1. Mold life expectancy

2. Overall expense of the mold

3. How to avoid any obstacles

When Should Mold Flow Analysis be Used?

Mold flow analysis is conducted using software after tool design but prior to tool kickoff. Utilizing a selected gate area and material properties, the software simulates how the part will fill during the molding process. Various data points can be evaluated such as pressure, fill time, and melt temperature. Doing so permits optimization of the operation before tool fabrication begins.

Mold flow analysis (MFA) is a software simulation showing how resin will flow through a mold. Once a mold design is complete MFA is used to determine the number of gates and their locations, show material choke points and hot spots, predict short fill and sink mark locations, and many other critical parameters needed to optimize a mold design for a repeatable, consistent molding process.

This analysis is vital to predicting what to anticipate during the molding process including:

- Shrinkage compensation for tooling tolerances

- Warpage issues

- Handling conditions

- Material Temperature and shot parameter optimization

- Flow-induced shear stress

- Weld line area

- Mold and Coolant temperature

- And more

1. Mold life expectancy

2. Overall expense of the mold

3. How to avoid any obstacles

When Should Mold Flow Analysis be Used?

Mold flow analysis is conducted using software after tool design but prior to tool kickoff. Utilizing a selected gate area and material properties, the software simulates how the part will fill during the molding process. Various data points can be evaluated such as pressure, fill time, and melt temperature. Doing so permits optimization of the operation before tool fabrication begins.

|

The Benefits to MoldFlow Analysis:

|

|